ANISOPRINT

Anisoprint is a team united by a common goal – to introduce a new, globally demanded industrial manufacturing technology for optimized structure made of composite materials.

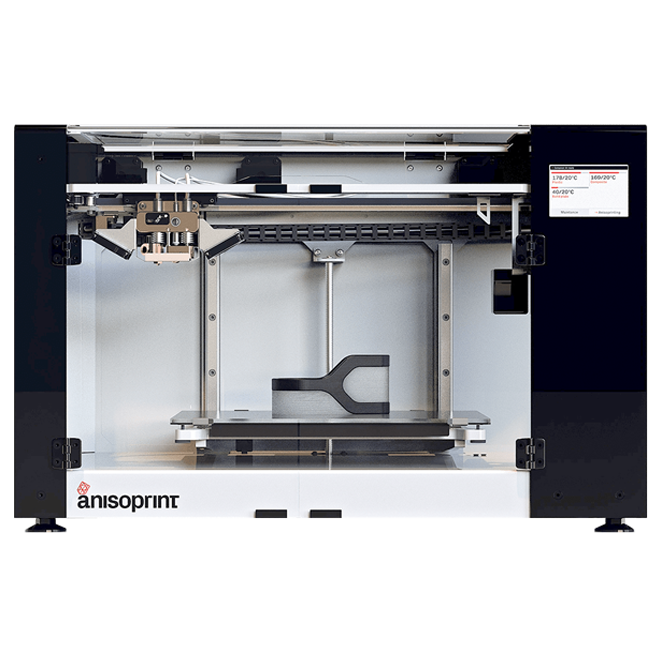

Founded in 2015, Anisoprint develops desktop 3D printers capable of processing composite materials, producing structural parts with increased mechanical properties. In 2017, the company presented the latest iteration of its continuous fiber-reinforced polymer (CFRP) composite material 3D printer at a conference in Skolkovo, Russia.

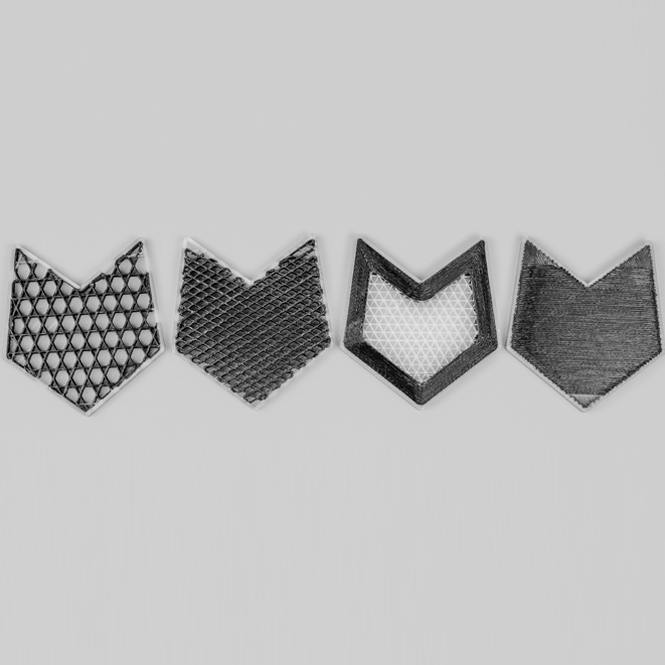

Anisoprint technology integrates a composite reinforcing fiber in the form of a tow (a coarse, broken fiber) made of thousands of ultrathin carbon monofilaments, into plastic during 3D printing. This improves adhesion between the polymers and the fiber. As a result, 3D printed parts 25 times stronger than pure plastic and 7 times lighter than steel are said to be produced.

The latest Robotic Solution print heads can be installed on similar desktop 3D printers and controlled by the company’s CAM software. It is currently being utilized by U.S. aerospace company Airbus, the Luxembourg Institute of Science and Technology (LIST) and the Technical University of Munich (TUM) for spare parts and tooling purposes. Anisoprint technology provides a wide range of applications in aerospace, automotive, healthcare, manufacturing, sport, transport – every area where strength and lightweight are required.