What is the VIT-SEDAXIS CoE for AM?

Additive Manufacturing is one of the key pillars of Industry 4.0 and helps organizations globally realize their product designs from Concept to Production with greater design freedom, reduced tooling cost and less material wastage.

This smart manufacturing process will revolutionize the way how man and machine collaborate efficiently, thus enabling factories of the future via a smarter, more connected ecosystem. To address this cultural shift, we at Sedaxis have established a Centre of Excellence for Additive Manufacturing (CoE for AM).

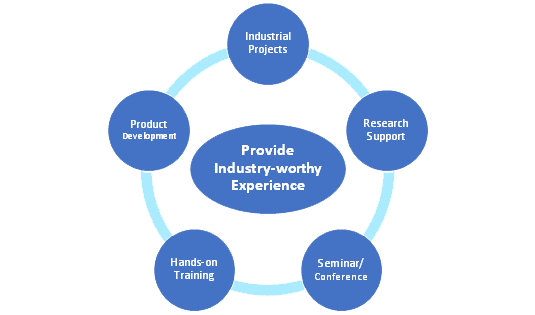

The CoE for AM is essentially a technology facility with various advanced 3D printing equipment, materials, software, tools and accessories. It serves to bridge the gap between academia and industry while preparing students for careers in Industry 4.0 and related research. It also helps industries (SMEs and Start-Ups) with affordable access cutting edge technology in 3D printing for product development, prototyping and small series production needs.

Scope of Services offered

- Trainings & Workshops

- Technical workshops for a better understanding and awareness of 3D Printing (3DP) technologies and applications

- Targeted workshops for identification of parts within company portfolio that can migrate to 3DP and identification of right technology and materials for execution

- DfAM (Design for Additive Manufacturing) workshops – presently in polymer and composites only, for students and industry professionals

- Using 3D Printing in metal/polymer/continuous composites/ceramics for R&D applications

- Skill upgradation for working professionals via theoretical and hands-on engagement on AM concepts and applications.

- Industry , SMEs, Start-Ups

- Re-design of parts and sub-assemblies wherever applicable

- 3D printing of parts using various technologies and

- Quality Inspection and Testing of parts (mechanical and NDT where and if applicable)

- 3D scanning of physical parts for re-engineering applications (to be launched in the near future)

- R&D

- Support revenue generating R&D projects of any government R&D and/or academic institutions.

- Independent R&D projects using open material, open platform printers at the CoE on a paid basis, with the support of the full-time manpower at the CoE.

- Technical support on any R&D printers separately procured from the machines sales division of Sedaxis.

- Academia

-

- Students under the supervision of the college faculty member(s) may visit the CoE in person for a more hands-on ‘touch, feel and learn’ experience of Additive Manufacturing technologies and applications.

- Faculty may send their PhD scholars and/or Post-Doctoral researchers to the Centre for any specific projects in relation to their dissertation thesis/research projects. On a case-to-case basis, they will be allowed to use the Centre’s resources to carry out research activities (strictly on a paid basis).

- Professors submitting research proposals in AM to government and other funding agencies can showcase the CoE as a model facility for the Principal Investigators and/or Government officials

- Sedaxis along with select staff from the CoE can collaborate with your University as an industrial partner for government funded projects. Terms and conditions of such a partnership will vary from project to project. Any costs expected to be incurred by Sedaxis as the industrial partner shall be budgeted into the project at the time of application. The Centre’s resources shall be made available towards the execution of any such project, upon mutual review and agreement by both parties.