Composite Fibers

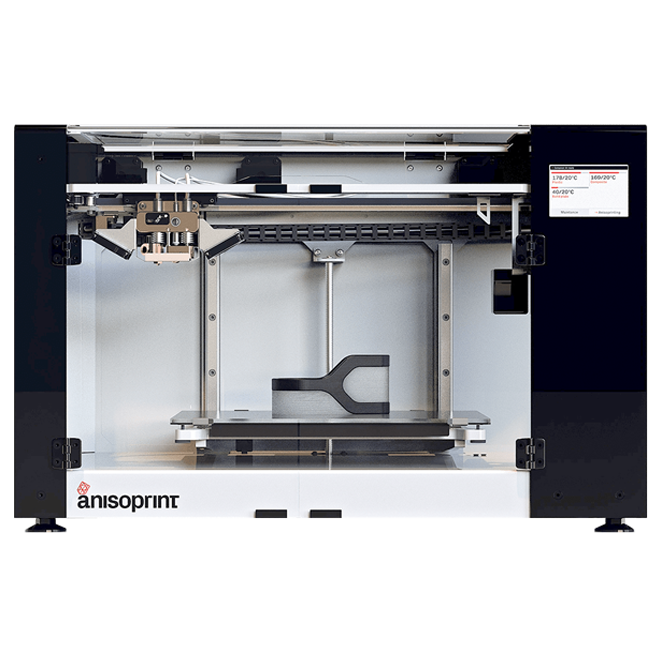

Composite Fiber Co-extrusion (CFC)

Composite fiber coextrusion is a core innovation in our products, and it significantly differs from the other approaches to 3D printing of composites with continuous fibers (prepreg, dry fiber coextrusion, lamination — they all have their limitations). In CFC technology, we reinforce plastic with continuous composite fibers directly during the printing process, not at a pre-stage like in other technologies. This approach allows usage of any plastic you want (PETG, ABS, PC, PLA, Nylon, etc) and changing the composite infill density.

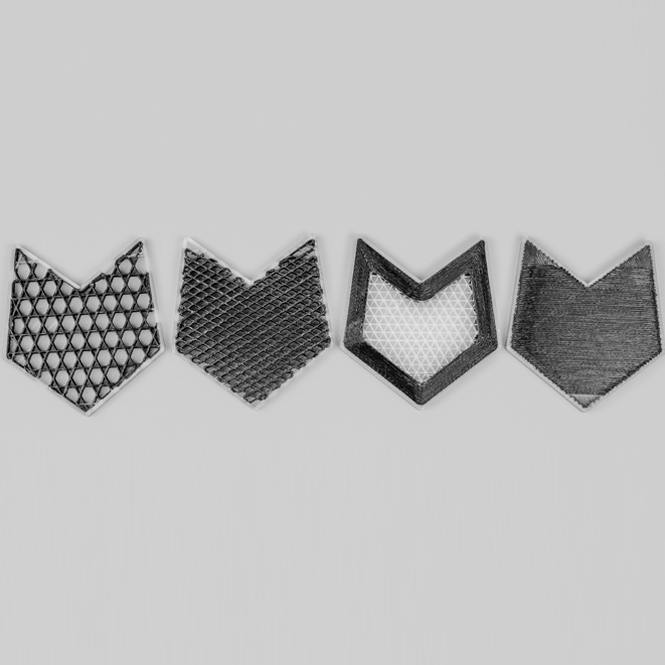

By varying the reinforcing materials, the direction of fibers and the density of the structure, we can make more optimal parts with intricate shapes, complex lattice structures, or bionic designs. The main challenge when printing with composites is associated with the nature of the materials. To create a composite, you must merge the reinforcement with the matrix material, which makes dissimilar reinforcing elements work together. This is not a simple process.

In most of the cases, the reinforcement is a fibrous material, which consists of long and thin microfibers, and the matrix is a viscous polymer. Merging these two while ensuring good impregnation of fibers with the polymer and good bonding between components is tough. It has two stages: first, we impregnate fibers with a special polymer, which has a low viscosity in an uncured state, then easily goes inside the fiber tow and bonds to it tightly. Then we heat it up and the polymers cures, morphing to a stiff and solid substance. This is done prior to the actual printing.

Composite fibers are then used as a reinforcement, pulling them through the nozzle together with plastic and the plastic bonds these fibers together as they are being shaped into a part’s structure. This is why the process is called co-extrusion. Such an approach allows choosing plastics with a certain chemical resistance, frictional properties, flame retardancy and/or other properties you want to make the final part many times stronger, even stronger than metal.