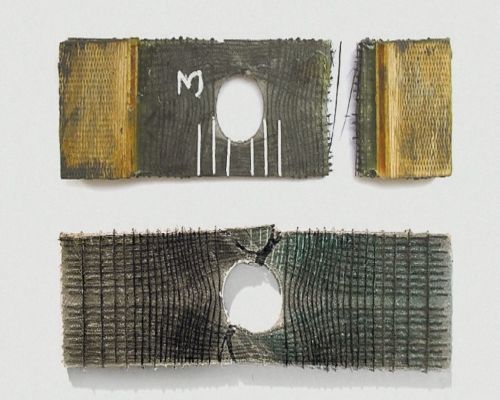

Perforated plate is a demo sample for application of developed sustainable reinforcement method of perforated items. The method and sample have been developed as part of graduate thesis prepared by magister at Space-Rocket Composite Structures Faculty of the Bauman Moscow State Technical University.

The approach provides reduction of stress in the vicinity of the hole. As the result the stress in the reinforcing fibers remains uniform through the structural element and the hole is no longer a stress concentrator. It improves the strength of the part without increasing the weight.

It is well known that holes are stress concentrators and, as a consequence, significantly reduce the strength of structural elements. Traditionally, to increase the strength of an element, a part thickness is increased. Disadvantage of such approach is that it leads to increasing of the part weight.

Anisoprinting implies fundamentally alternate approach, resulting in curvilinear reinforcing trajectories with the most effective response to distribution of loads in material. Anisopringting approach includes manufacturing of composite parts with complex internal structure. The demonstrator sample was manufactured on the Composer A4 CFC printer. Polyethylene terephthalate (PETG) was used as basic matrix material while CCF1.5k composite carbon fiber was used as the reinforcement.

The approach provides reduction of stress in the vicinity of the hole. As the result the stress in the reinforcing fibers remains uniform through the structural element and the hole is no longer a stress concentrator. It improves the strength of the part without increasing the weight.