Key Benefits

1. High-speed, low cost prototyping

R&D as an activity requires long investment cycles, several failed development efforts and high costs. 3D printing technologies can help reduce all of the above, thus resulting in reduced times and lower costs. This helps to put the focus back on the ingenuity of the research efforts rather than worry about budgets and timelines.

2. Reduce time between design iterations

In research and development, time is money. In a rapidly evolving world with fast-changing customer preferences, the need to accelerate development efforts is paramount. And this can be achieved by reducing the number of iterations to reach the predefined objectives. With simulations, both online and offline helping many industries perfect their product offering before goto-market, having physical prototypes quickly, within budget and as close to the actual production model, can greatly help in reducing this time between design iterations.

3. Highlights potential risk areas early on

By being able to prototype faster, R&D engineers are in a much better position to assess risk and failure modes faster and more accurately. This in turn reduces the chance of a failed product launch, thereby massively enhancing the market competitiveness of the company utilising such 3D printing technologies within their R&D set-up. Being able to identify a potential failure much earlier in the product development process saves time, effort and money.

4. Faster route to market

Faster design iterations means faster time-to-market. And by launching a newer, more improved version of an incumbent design in the market, faster than your closest competition, puts the organization in a unique first-mover advantage and helps them gain market share early on.

5. Inspires Innovation

R&D is about pushing boundaries and getting more performance at less cost, a better user experience with simpler designs and safer products with longer lifetimes. It is innovation at its purest. And 3D printing, with it is unique advantages of ‘complexity at no extra cost’ and ‘limited only by your imagination’, truly helps R&D teams successfully push those boundaries to make products better than their best.

Applications

Printing of Elaborately Shaped Composites

Currently, much research is carried out to explore possibilities of printing composite structures using a few or even several materials simultaneously. Composite structures are now manufactured using traditional production technologies, but 3D printing makes it possible to quickly manufacture composite products of very complex configurations, having mechanical properties characteristic to many different materials.

MULTI-MATERIAL PRINTING OF METAL OBJECTS

With advances in 3D printing, you can print a single part using different materials, thereby immediately producing a design detail with the elements of various materials, e.g., a heat exchanger printed with both stainless steel and copper. This would make 3D printing a faster, cheaper development process compared with traditional production techniques while enabling to push the performance boundaries on part designs.

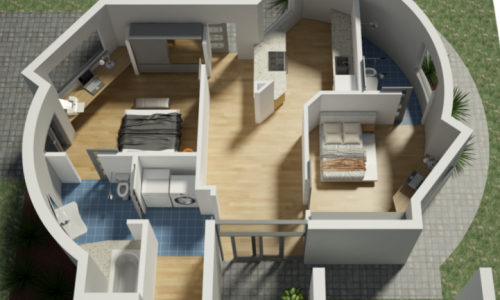

Living in a Printed House

The future of sustainable and affordable human living is fast arriving. Companies are beginning to develop the 3d printing robotics, software and advanced materials capable of 3d printing entire communities with several 1000+ sq. ft. homes. Using 3D printing technology, one can print a custom home and do it quicker with less waste and at a lower cost than traditional homebuilding methods. This is no longer science fiction but a scientific fact!

3D Printed Objects of Microworld

It is much harder to grasp the possibility of printing extremely minute objects that cannot be seen by the human eye. 3D printing technology can be widely applied in process engineering, biomedicine, textile and other industries. For example, in process engineering 3D printing of nano/microstructures can be used to print various filter materials. By insertion of bioactive medicinal substances into the printing filaments, we can also create a new generation of drug carriers with this technology.