Benefits of Continuous fiber-reinforced composites

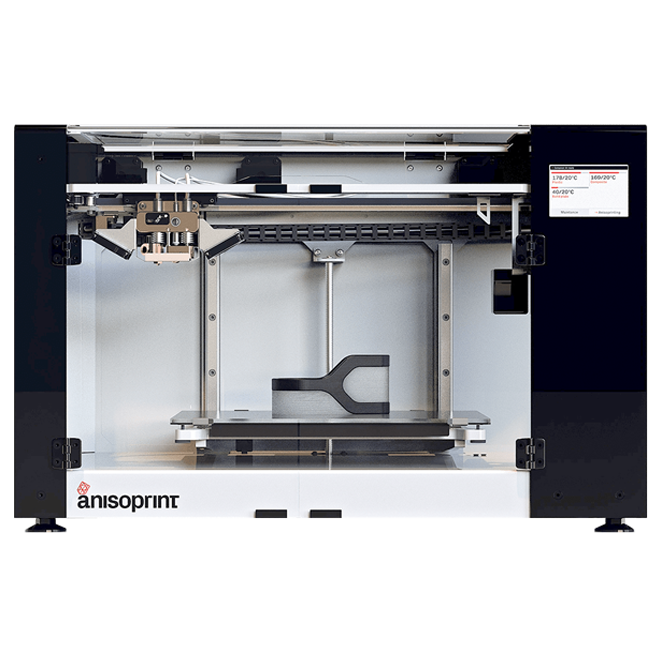

- Continuous fiber – reinforced composites:

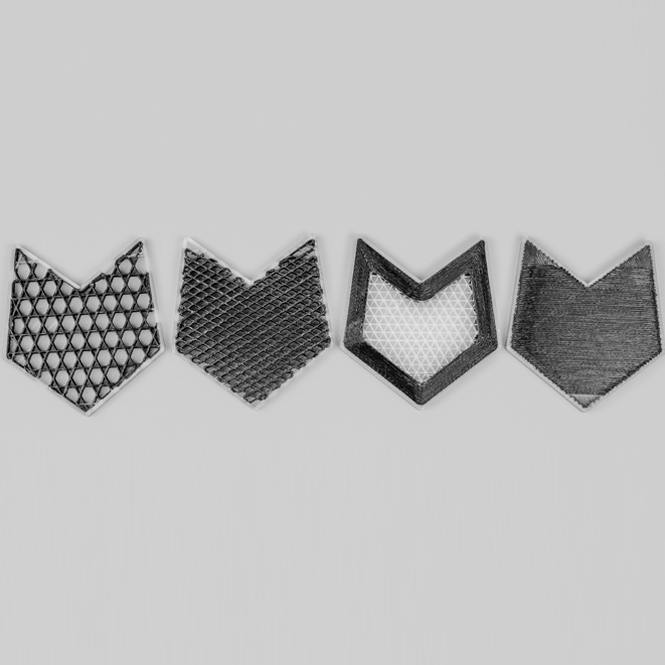

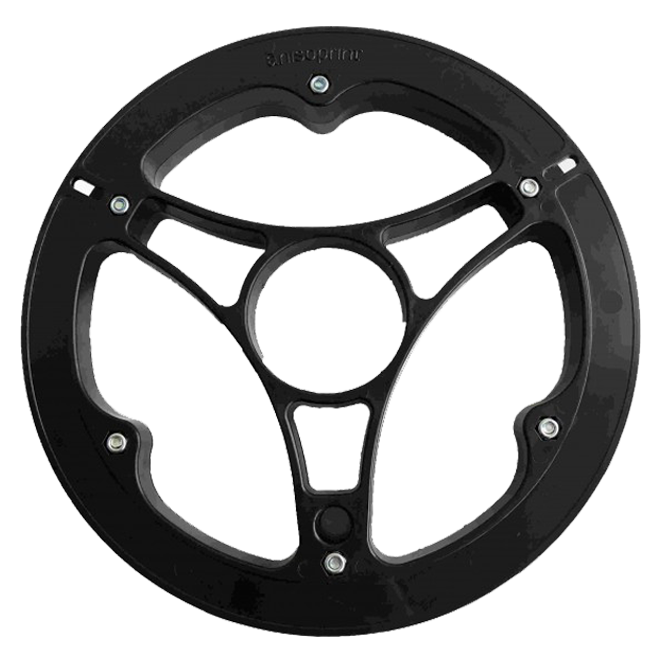

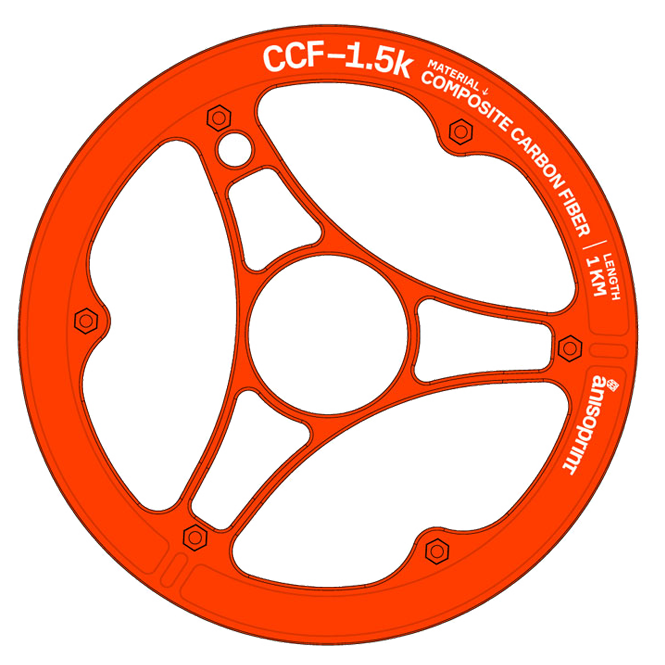

30 times stronger than pure plastic, 2 times stronger & lighter than aluminium; - Optimal composite structures: lattice reinforcement — minimum weight, price and production time for the required strength.

- arbitrary (custom) trajectories of fiber laying..

- Open material system: use any plastic as a matrix.

- open G-code.

- non-cloud software

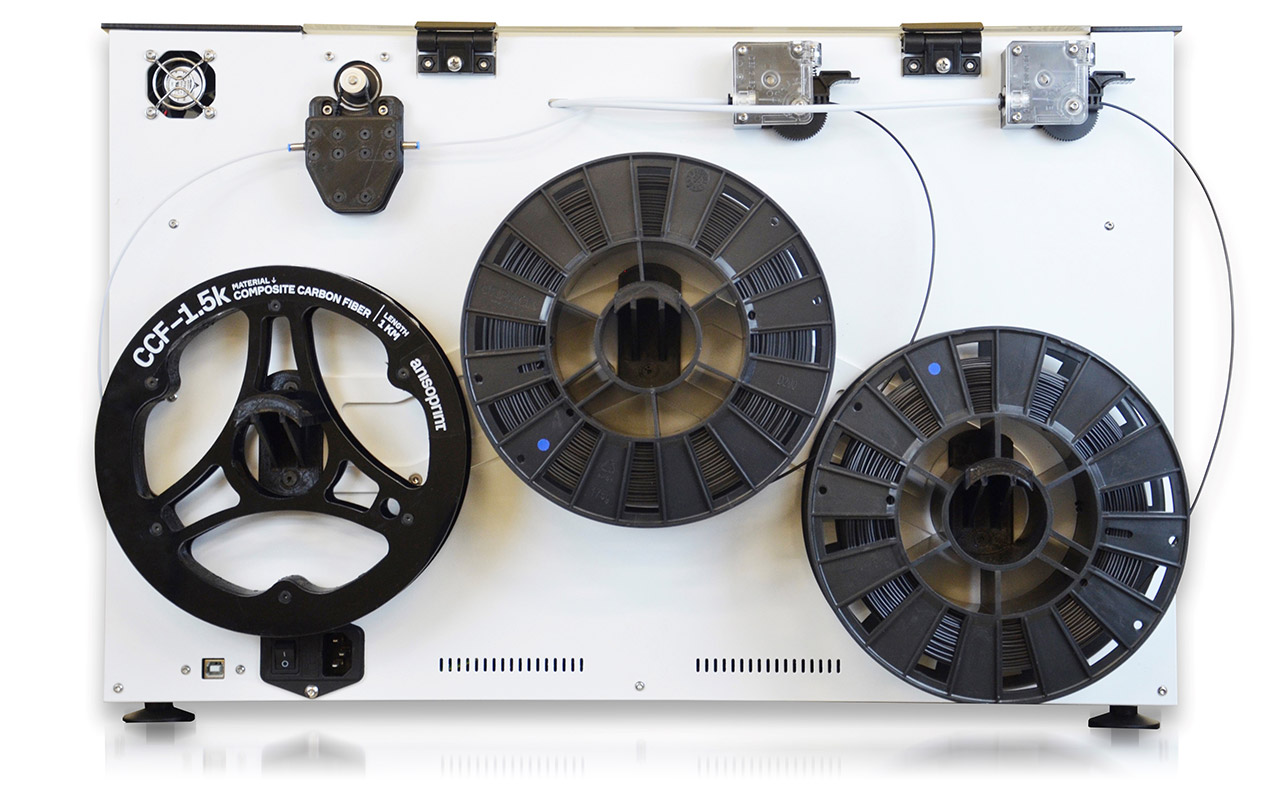

- Two reinforcing materials: CCF (based on carbon) and CBF (based on basalt).

- Complete control over fiber path generation with the slicing software Aura.

Low-cost part production

A 750m spool will be enough to fabricate a fully composite 55х55х55mm cube or a fully composite A4-sized plate with a thickness of 2.5mm. The volume ratio of carbon or basalt fiber in the final product is about 25%.